General Information

The following information provides general equipment and service information that will help you to use this manual to properly repair and maintain the bike.

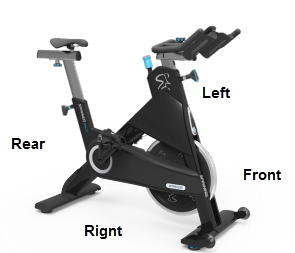

The equipment orientation (front, right, left, back) used in manual is referenced to a user sitting on the equipment facing the handlebars.

Serial Numbers

Tools

Required service and repair tools:

|

|

|

|

|

|

|

|

|

|

|

Notes: |

|

This table provides a summary of system component specifications.

| System Component | Specification |

|---|---|

| Pedal Torque | 33 ft-lb (45 N•m) |

| Drive Belt Tension | 60 +/- 5 lbs (27 */- 2 kgs) |

| Generator Belt Tension | 1/2 in (1.3 cm) up/dwn travel |

| Stabilizer fastener Torque | 15.6 ft-lbs (21 N•m) |

| Axle Nut Torque | 29.5 ft-lbs (40 Nm) |

.

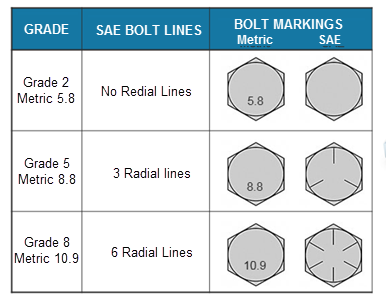

Bolt grade markings are used to categorize bolts according to the bolt material, manufacturing process, and mechanical properties.The grade of the bolt is stamped on the head of the bolt.

US SAE bolts: The bolt grade markings are determined by the number of the lines stamped on the head of the bolt. The number of lines is always two less than the grade of the bolt. Count the lines, add two, and you can determine the grade of the bolt.

Metric bolts: On metric bolts, the bolt grade is identified by a bolt grade number stamped on the head of the bolt.

|

|

CAUTION: Always replace bolts with the same grade bolt. If you don’t know the grade of the replacement bolt – DO NOT USE THE BOLT. |

Bolt Grade Markings Chart

Example bolt grades used on Precor equipment (may not represent all bolt grades). Always match the replacement bolt grade marking to the removed bott grade marking.

|

|

IMPORTANT: Always purchase OEM replacement parts and hardware from Precor. If you use parts not approved by Precor, you could void the Precor Limited Warranty. Use of parts not approved by Precor may cause injury. |

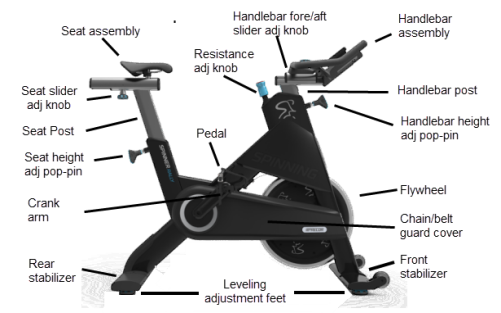

Major Assembly and Parts Location

Exploded View Diagram and Parts List

There is a copy of the parts Exploded View Diagram and Parts Identification List included in the Parts chapter that you can use as a quick reference. It is recommended that you go to the servicer partners ![]() Precor Connect website to view the most current parts information including the Exploded View Diagram and Parts Identification List.

Precor Connect website to view the most current parts information including the Exploded View Diagram and Parts Identification List.

Only use products from the following list of approved lubricants:

| Lubricant | Description |

|---|---|

| Grease |

Use only NLGI class 2 PTFE synthetic grade grease. Use of unapproved lubricants may void the product warranty. Recommended brands (or equivalent): • Mobil 1® synthetic grease • Super Lube® with Teflon |

|

|

CAUTION: Do not use petroleum based lubricants on mechanical components such as the lift, as this may result in degradation of nylon gearing mechanisms. Use only synthetic lubricants such as "Super Lube with Teflon" or "Mobile One Synthetic" grease (RED). |

Only use the following approved cleaning products to safely clean and prevent damage to the machine surfaces.

Approved Cleaning Products:

- General Equipment Surfaces:

- 1 part mild soap to 30 parts water (recommend Simple Green® cleaner or equivalent).

- Athletic equipment cleaner, 9x7 pre-saturated wipes (ATHLETIX PRODUCTS).

- Enivir O Safe oxygen enhanced cleaner or Enviro Safe glass and multitask cleaner concentrate.

- Consoles and PVSPersonal Viewing System display.: a diluted solution of one part 91% Isopropyl alcohol to one part water.

Cleaning Procedure

- Wipe down equipment using a soft lint-free cloth using only the recommended cleaning solution. Always spray cleaning solution directly onto the cleaning cloth and not directly onto the equipment surface to avoid equipment damage due to excessive moisture.

|

|

CAUTION: Do not use acidic cleaners and do not spray directly onto the equipment surfaces. |

- Rinse surfaces using a clean lint-free cloth dampened with water only.

- Then completely dry with another clean lint-free cloth.